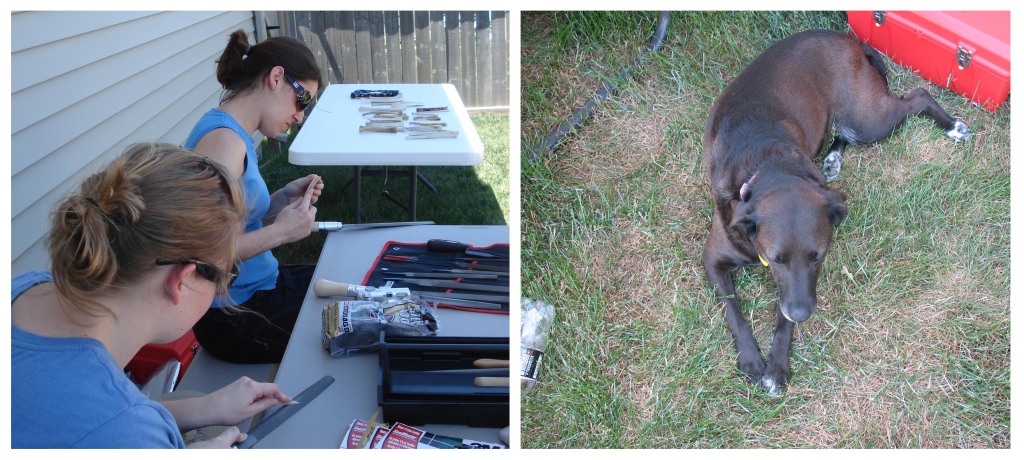

Last week the preservation department staff spent a lovely (and extremely sunny) afternoon learning to make our own bone tools from the remains of deer and cows. Melissa, having received instruction some years ago in a workshop with Jim Croft, demonstrated the methods of shaping bone with hand tools. You can find her previous post on bones here.

Sanding bone can get pretty messy, so Mindy provided a nice outdoor space for us with tables and chairs. When we all arrived, Melissa laid out a selection of cleaned bone pieces graciously provided by a local biological anthropologist and her swarm of dermestid beetles. We were glad to receive the assistance of those little guys, as they apparently saved us a great deal of skinning, stripping, boiling, burying… and waiting.

The entire process of shaping the bone requires a heavy cutting tool (such as a hatchet), a variety of rasps and files, sandpapers, and steel wool.

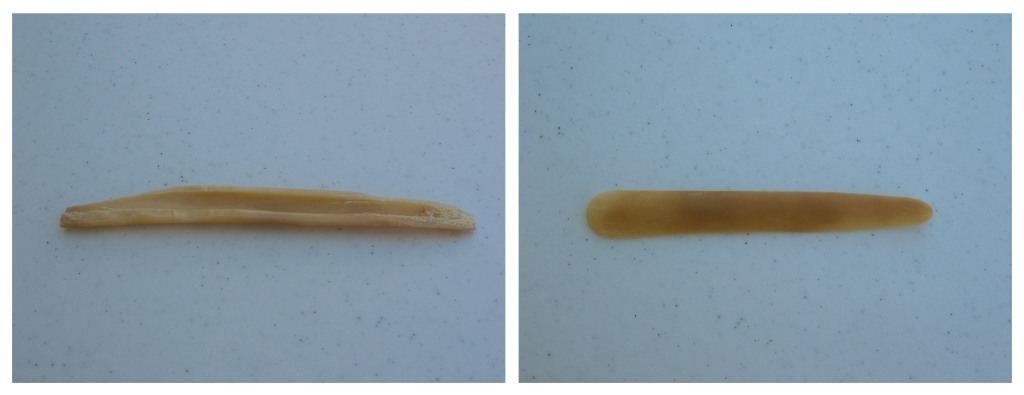

After selecting a bone with an appealing length, shape, and or heft, we began shaving and chipping pieces away with the hatchet. Bone can be carved not unlike wood, and the rough shape of the tool is achieved rather quickly. After shaping with the hatchet, we took turns working with the roughest rasp to whittle away the protrusions.

This process continued for some time – the shape of our tool-to-be emerging as we switched to increasingly finer rasps and files.

1 Comment